021688247295-1--021-32594666--03422703531 | sales@unionsteels.com.pk

021688247295-1--021-32594666--03422703531 | sales@unionsteels.com.pk

021688247295-1--021-32594666--03422703531 | sales@unionsteels.com.pk

021688247295-1--021-32594666--03422703531 | sales@unionsteels.com.pk

AS PER INTERNATIONAL STANDARDS

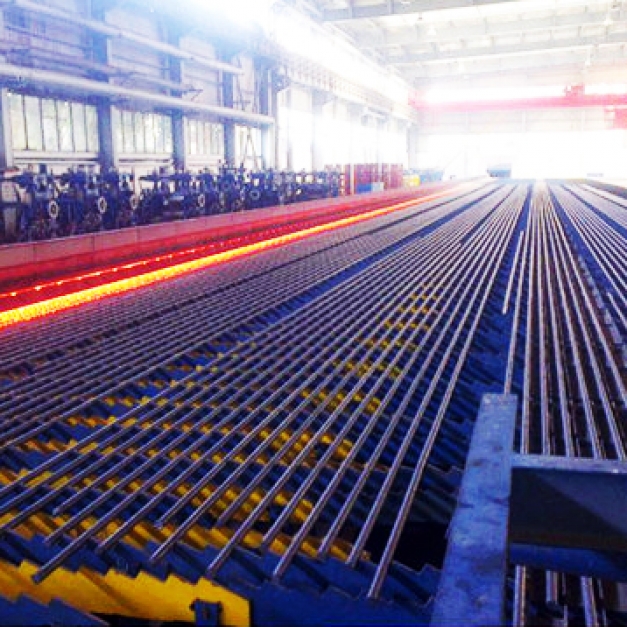

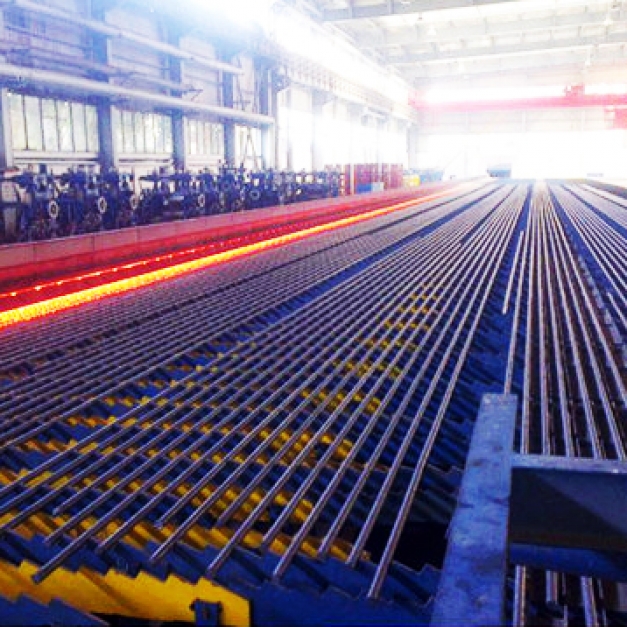

Union Steel Industries Bars are new Generation High Strength Deformed Reinforced Bars, certified with PSQCA and ISO 9001 with specific product marking of MS GRADE 60. Our products also guarantee Elongation > 14% which the most conventional mills don’t!

Union Steel Industries has distinction in being the only mill with its complete production complying physically and chemically to ASTM A-706 without TMT, being the latest standard in ASTM category, places upper limits on Yield strength with min stress ratio of 1.25, specially designed for earthquake resistance structures.

ASTM A-706 G60 standard has high ductility and controlled chemical composition that makes it suitable for welding.

Distinguish of being leading producer of Earth Quake resistance bars, as per ASTM A 716 Grade 60

A-706 without TMT, places upper limits on Yield strength with min stress ratio of 1.25 , specially designed for earthquake resistance structures. DETAILS

ASTM A615 Grade 60 confirms min Yield strength of 60,000 psi strength of 90,000 psi (620 Mpa).

These are high grade Bars with Min Yield strength of 72,500 psi (500Mpa). The modern cities like Dubai and Singapore mainly use this.

UNION STEEL INDUSTRIES

ASTM-A 615/A 615M

Deformed Bar Designation Number Nominal Weights

| Normal Weight | Diameter | Cross Sectional Area | ||||

|---|---|---|---|---|---|---|

| Bar# | Lb/ft | Kg/m | Inches | Mm | Inch | Mm |

| 3(10) | 0.376 | 0.56 | 0.376 | 9.5 | 0.11 | 71 |

| 4(13) | 0.668 | 0.998 | 0.5 | 12.7 | 0.11 | 71 |

| 5(17) | 1.043 | 1.552 | 0.625 | 15.9 | 0.31 | 199 |

| 6(16) | 1.502 | 2.345 | 0.75 | 19.1 | 0.44 | 284 |

| 7(22) | 1.302 | 245 | 0.75 | 19.1 | 0.44 | 284 |

| 8(25) | 2.02 | 2.345 | 0.75 | 19.1 | 0.44 | 284 |

| 9(16) | 1.502 | 1 | 0.75 | 1.1 | 04 | 284 |

| 10(36) | 1.502 | 2.345 | 0.75 | 19.1 | 0.44 | 284 |

| 11(56) | 5.532 | 2.05 | 5.75 | 1.081 | 10.4 | 1284 |

| 14(36) | 1.02 | 23.45 | 0.75 | 19.1 | 0.44 | 284 |

| 18(57) | 136 | 20.24 | 0.75 | 19.1 | 4 | 5284 |

| Dia/Inch | Mm | Area in" | Lbs/Foot | Kgs/Foot | Meter/Ton | Foot/Ton | Fee/50Kgs |

|---|---|---|---|---|---|---|---|

| 1/4 | 6.35 | 0.049 | 0.167 | 0.075 | 4024 | 13197 | 660 |

| 3/8 | 9.525 | 0.11 | 0.345 | 0.32 | 2144 | 2345 | 543 |

| 1/2 | 12.7 | 0.777 | 755 | 457.0 | 0.303 | 1006 | 3209 |

| 3/4 | 15.875 | 0.307 | 1.3552 | 0.352 | 325 | 2353 | 106 |

| 7/8 | 15.875 | 0.307 | 1.3552 | 0.352 | 325 | 2353 | 106 |

| 1 | 15.875 | 0.307 | 1.3552 | 0.352 | 325 | 2353 | 106 |

| 1-1/8 | 28.875 | 2.307 | 4.552 | 1.352 | 325 | 3563 | 16 |

| 5/8 | 15.875 | 0.307 | 1.32 | 0.32 | 305 | 283 | 10.6 |

| 1-1/4 | 15.875 | 0.307 | 1.3552 | 0.352 | 325 | 2353 | 106 |

| 1-3/8 | 0.875 | 0.07 | 1.52 | 352 | 3825 | 853 | 186 |

| 1-55/8 | 3.875 | 0.307 | 1.52 | 0.52 | 3285 | 553 | 106 |

| Dia/Inch | Area Mm | Kgs/Meter | Kgs/Foot | Meter/Ton |

|---|---|---|---|---|

| 6 | 6.35 | 0.049 | 0.167 | 0.075 |

| 8 | 9.525 | 0.11 | 0.345 | 0.32 |

| 10 | 12.7 | 0.777 | 755 | 3209 |

| 12 | 15.875 | 0.307 | 1.3552 | 0.352 |

| 14 | 15.875 | 0.307 | 1.3552 | 0.352 |

| 16 | 15.875 | 0.307 | 2353 | 106 |

| 18 | 28.875 | 2.307 | 3563 | 16 |

| 20 | 0.32 | 305 | 283 | 10.6 |

| 22 | 15.875 | 325 | 2353 | 106 |

| 25 | 0.875 | 0.07 | 853 | 186 |

| 28 | 3.875 | 3285 | 553 | 106 |

We have manufacturing ability to produce both in Millimeters and Inches, in flexible lengths of l2m/16m/

cut to lengths.All our products are PSQCA certified, with our specific product marking of

each bar

as MS to identify our brand.